With a history reaching back to the days of ICI, our knowledge and understanding of the Polymer manufacturing marketplace is difficult to match. Many of our longest standing clients are leading names in the sector and continue to be at the forefront of developments to the current day.

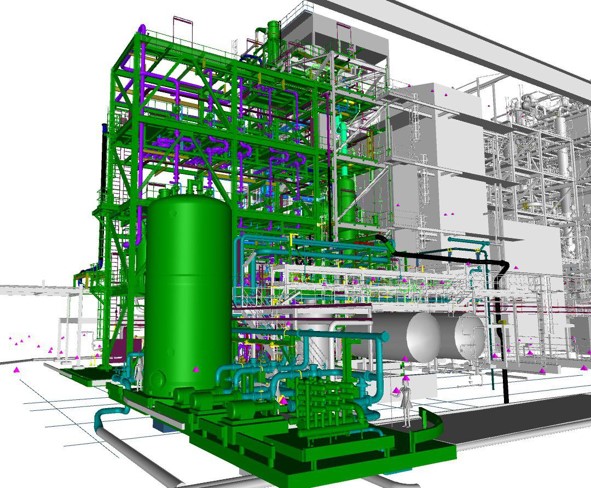

Whether it is a Monomer, Polymer, Resin or other base level plastic derivative, we have the Process and related Engineering capability to support the development of both new and expansion projects.

Addison are experts in site improvements, ‘cut and carve’ projects where the site has to remain live during construction and working with clients to realise a new facility from the concept stage. In addition, we can work with you to maximise output on existing plant by embedding our Process team into your operation.

Site Improvements

Once a plant is built and operational performance has reached capacity, the next logical step for increased capability is incremental debottlenecking. Identifying areas with opportunities and adapting existing facilities to develop these areas is often the most cost-effective and efficient solution for increasing production.

Typically, an existing plant can be debottlenecked for a fraction of the cost of building new facilities. Some plants have been debottlenecked many times over, so that their actual capacity is several times larger than that of their original design. Maximising your existing plant capacity with little capital expenditure can greatly increase profitability. The advantage of debottlenecking is that running costs stay relatively constant whilst income increases.