As befits our ICI background, we have extensive experience in working with clients across the Chemical sector. Our policies and procedures reflect the requirements of the environments in which our clients operate and we are specialists in delivering intricate ‘Cut and Carve’ projects on live COMAH sites.

We can support site expansion, refurbishment or simple changeover projects. Whether these last for several months, and require detailed design, planning and construction, or a quick turnaround within days, we are in a position to respond accordingly. Soem examples of the type of work we offer are below.

MONOMER REPLACEMENT PROJECT

Borosilicate Plant Modernisation

50% Steam Raising Capacity Increase

Highlights:

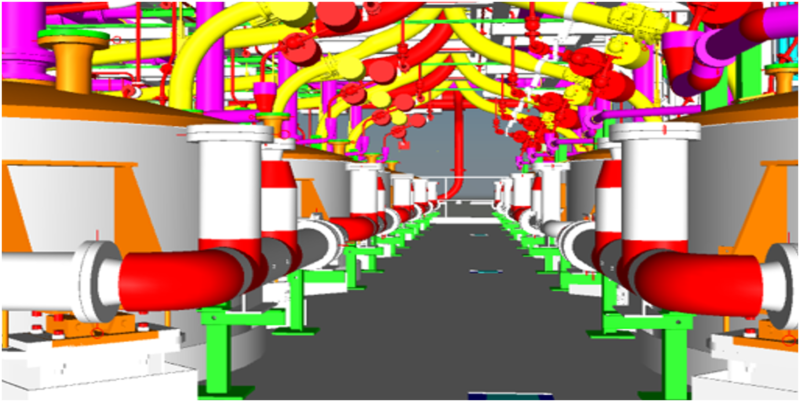

- Multi discipline, mechanical, piping, civil, structural design

- Procurement and Document Control support services

- 5,000m of pipe work

- Design work completed on site as client request

- Mechanical design completed in E3D

- Civil/Structural design completed in TEKLA

- Full laser scan of the site (328 scan position, 1.5TB of data)

GASIL WASHER EXPANSION

Principal CDM Role

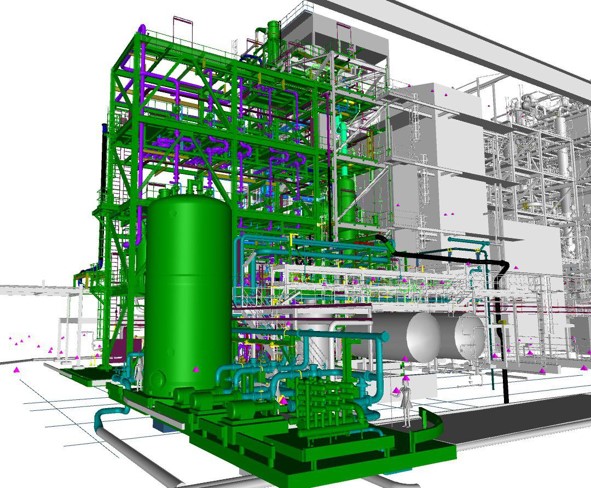

- Full laser scan of plant.

- Multi-discipline design completed:

- Piping design

- EC&I design

- Civil/structural design

- Process support

- Supporting Services

- Equipment engineering

- Procurement

- Project Management

- Construction Management

- 5,000m of intricate pipe work designed.

- 15 duplex washer vessels installed.

- Demolition of existing Buell dryer.

- Design and engineering of large structure, pumphouse and associated silo structure.

- +/-10% FEEP completed prior to detail design