Addison Precision utilise the latest in MRP/Scheduling & Machine Tool Monitoring software in order to finitely control & monitor all aspects of the manufacturing processes.

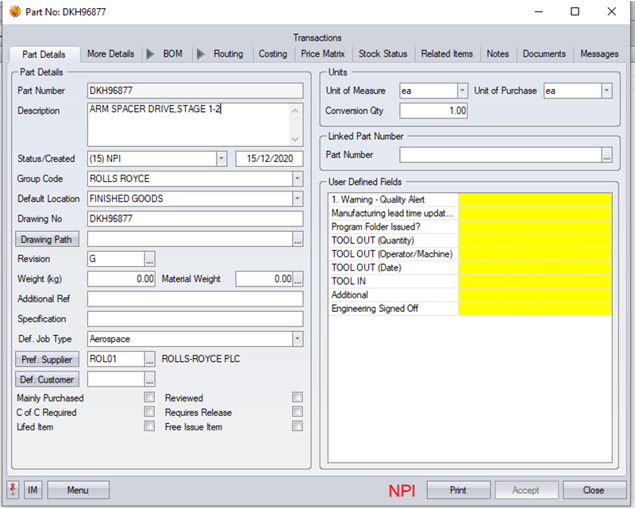

Integrated MRP

Progress Plus is a fully integrated MRP system used in every part of Addison Precision’s day-to-day management. This essential tool is key when making business decisions from quoting to cost monitoring, quality control to supply chain management. Progress Plus allows the business to delve into the details through its reporting system, enabling continuous improvement with the data it provides.

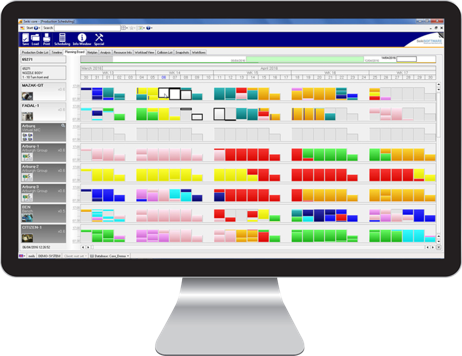

Integrated Scheduling

Alongside Progress Plus, Seiki System’s scheduling and machine monitoring software links directly to the MRP system to provide a high standard of workload planning, distribution and overall equipment effectiveness measures, to ensure that work is delivered to the customer on time, conforming, and at an unbeatable price.

Machine Tool Monitoring & WIP Booking

In addition to our fully integrated scheduling system we also utilise the latest WIP Booking and machine tool monitoring software, giving us a detailed ‘real-time’ over view of our manufacturing activities.

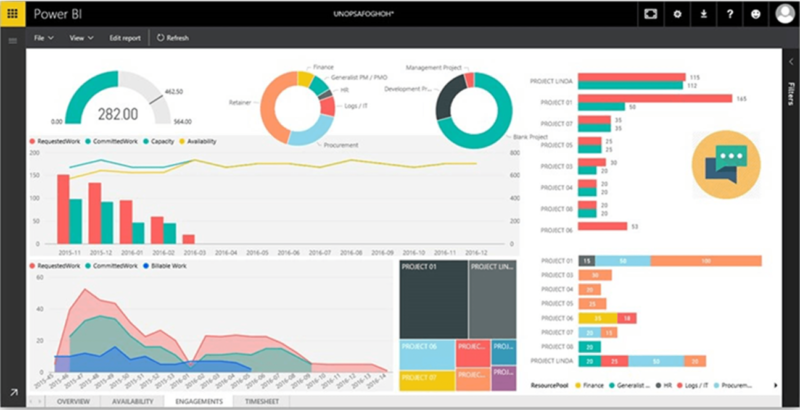

Performance Monitoring KPIs

Data capture in our manufacturing environment is imperative, enabling the business to continually monitor and measure daily performance. We have developed a whole range of KPIs directly interlinked with our MRP/Scheduling system which gives us “real time data”, enabling our management team to make real-time decisions.