| Or…do you have your project under control… |

Over the years, we have seen two constants around both large and small projects. The common thread is that, whilst projects kick-off with the best intentions in mind, it’s very easy for them to go off track if not controlled properly.

What’s the biggest cause of cost and time overrun? A simple case of allowing the goalposts to be moved during the project.

The impact, as we’ll demonstrate below, even of a small change, can be significant.

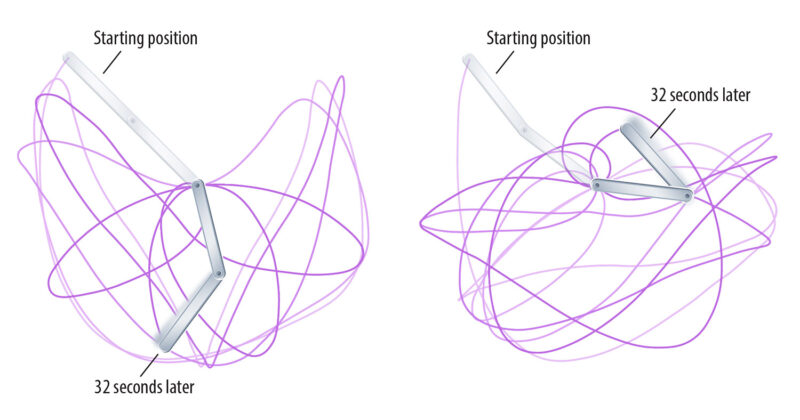

Why Butterflies?

In chaos theory, the butterfly effect is the sensitive dependence on initial conditions in which a small change in one state of a deterministic nonlinear system can result in large differences in a later state.

Put more simply, a small change can have a dramatic effect, not least on finances and most definitely on timescales.

What are we used to seeing?

- Client organisations running lean and short of resources

- Projects where the FEL processes are incorrectly applied

- Unfamiliarity with project processes causing late changes

- Lack of understanding of the impact of changes (and understandable irritation at the costs).

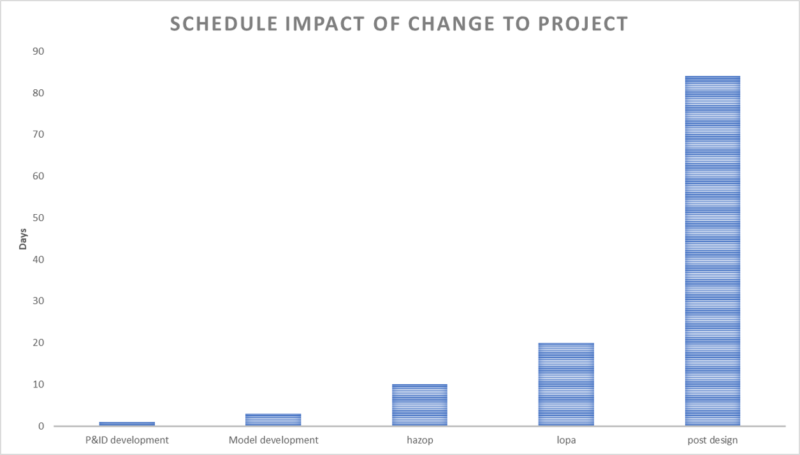

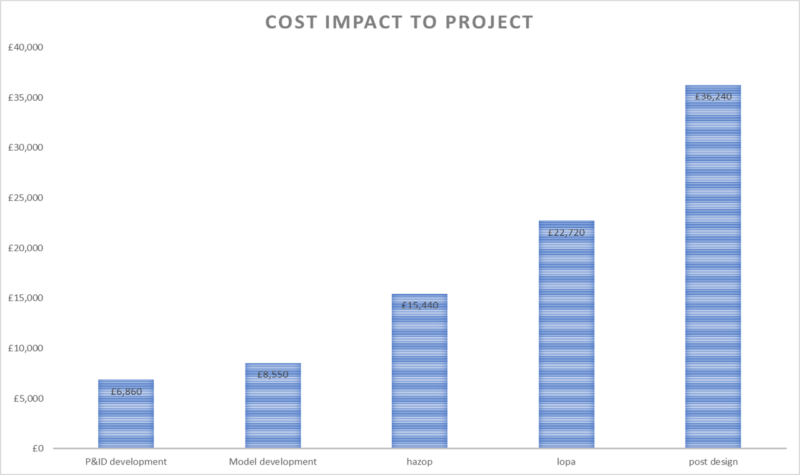

A real world scenario – changing a pump

- This pump is a change to a large project

- We will look at the cost impact of the pump at various stages of the project lifecycle, including engineering requirement

- The pump is a water pump pumping about 5m3/h at 20m head. Capital cost is about £4k

Stage 1- identification of pump at P&ID development

- Client/Contractor Process engineer

- Expected cost/schedule impact

- Pump cost £4k design impact 44 hours

- Schedule impact 1 day to overall project

Stage 2- identification of pump during model development 30% review

- Client/Contractor, Process, structural, piping, project engineer

- Expected cost/schedule impact

- Pump cost £4k design impact 70 hours

- Schedule impact 2-3 day to overall project

Stage 3- identification of pump during HAZOP

- Client/Contractor, Process, structural, piping, electrical, instrumentation, project engineer, HAZOP lead

- Expected cost/schedule impact

- Pump cost £4k design impact 176 hours

- Schedule impact 1-2 weeks to overall project

Stage 4- identification of pump during LOPA

- Client/Contractor, Process, structural, piping, electrical, instrumentation, project engineer, LOPA lead

- Expected cost/schedule impact

- Pump cost £4k design impact 288 hours

- Schedule impact 3-4 weeks to overall project

Stage 5 – identification of pump post design phase

- Client/Contractor, Process, structural, piping, electrical, instrumentation, project engineer, HAZOP/LOPA lead

- Expected cost/schedule impact

- Pump cost £4k design impact 496 hours

- Schedule impact 12 weeks to overall project

So what do we do about it?

- Commit a slightly higher proportion of funds and effort to the start of a project.

- Respect the FEL process.

- Engage with designer early to assist with project development.

- Leverage designer skills to assist you.

- Early flowsheet review.

- Don’t skimp on upfront project controls!